About 3D Printing

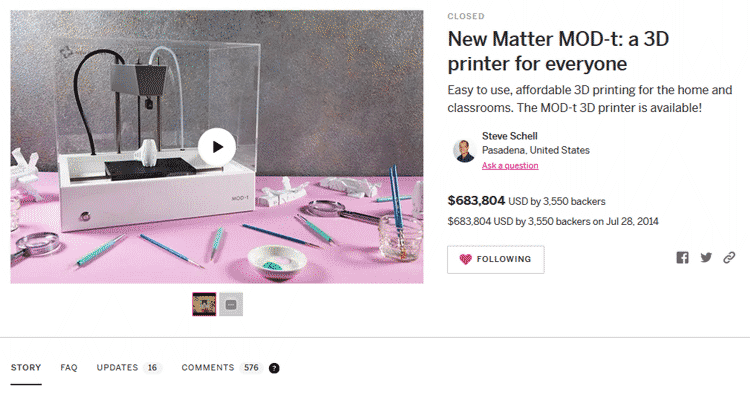

In 2014 I helped fund an Indiegogo project, the New Matter Mod-T: a 3D printer for everyone. It was my first foray into 3D printing. After a painfully long wait my printer showed up. I was giddy. The presentation was spectacular, the lines were sleek and inviting, and it looked like it had delivered on the promise.

I began printing and printing. And filling boxes with scrapped parts and partial prints. Layer shifts, dead hot-ends, lack of proper adhesion to the build surface, these things were tricky. Not only that but the build plate was tiny. Just big enough to “print a phone case”. I doubt I could print one for my current phone though.

Undeterred I encouraged Mrs3D to enter a contest they had giving multiple printers and a ton of PLA filament to teachers for their classrooms. She did, and ended up with with 3 printers and around 18 rolls of filament! She used them to make fossils. She taught the kids how to make their names and print them. She STEAMed them like crazy.

In the end though, they just weren’t reliable enough to use in any meaningful way. I printed a Mandalorian helmet long before there was a “The Mandalorian” and had to break it into 12 parts. Each part had to be reprinted several times due to layer shift issues, or a crashing head, or whatever the confounded issue would be with that particular print. I was having fun making things, but not really making much that was useful or even aesthetically pleasing. Some Christmas ornaments, parts for a big WiFi project, several Raspberry Pi cases, but there were just so many limitations with both the printer and PLA itself.

PLA is great for beginners. It is easy to print. It is rigid. It comes in a massive variety of colors and styles. It is also, above all, cheap. And that is good. Because when you are beginning you burn through a ton of wasted filament. I have the boxes of scrap to show for it. Not only that, but due to the low print temperatures, a few hours in a hot car will destroy even the best print.

So if that was my initial experience with 3D printing, why start a 3D printing company?

That comes down to my second printer.

When it came time to get my second printer, I decided to get the best one I could. It was a Prusa i3 MK3s kit. Along with it, I was introduced to PETG as a filament. The Prusa was a whole different animal. The print bed is a dream to print on. Don’t let anyone fool you, it is still fussy, and can be aggravating. That said, the larger build area, the increased reliability, and the ability to print in PETG transformed my experience printing. Instead of printing something 4, 5, even 6 times just to get a halfway useful print, once I got it tuned in it became the exception that a print would fail. When it did, it was usually me. Cheap filament, not cleaning the bed, not cleaning the head, stuff like that.

I began printing actually useful items.

The hook that came with the shower caddy we bought wouldn’t fit over our shower sides. A little while in CAD and a very serviceable, and even nice looking part came out that was as strong as the original, but custom fit to our needs.

There aren’t any license plate adapters for motorcycle sized plates to fit on JDM cars. A pair of calipers, and a little time in CAD, and I have a very clean looking adapter that will hold up to just about anything.

Suddenly I could make functional, aesthetically pleasing parts on a reliable enough printer that I could allow myself to be disappointed when a print fails.

Even with that, we realized very quickly that as much fun as I have making these things run, I am nuts. Most people have neither the inclination nor the patience to deal with it. 3D printers are, unfortunately, the realm of hobbyists and professionals.

So with that in mind, we here at 3D PrintFly hope to bring the ability to get great, useful 3D prints to people who would otherwise not even think about 3D printing as an option. Let us know what you need, and we will see if we can make it happen. We are expanding our offerings and variety of printers to do just that!